What Is a Ballasted Roofing System?

A ballasted roofing system refers to a method of installing single-ply PVC roofing membranes by securing them with the weight of ballast materials—such as concrete pavers, aggregate, or soil—instead of mechanical fasteners or adhesives. This technique relies on the gravitational force of the ballast to resist wind uplift, creating a non-penetrative waterproofing solution. The system is ideal for applications where roof deck penetration must be avoided, such as green roofs or occupied rooftops.

How Does It Work?

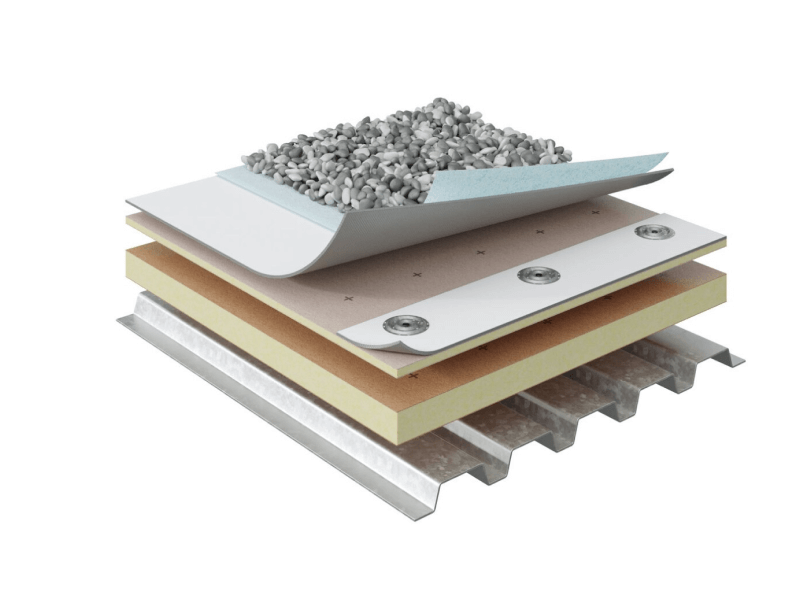

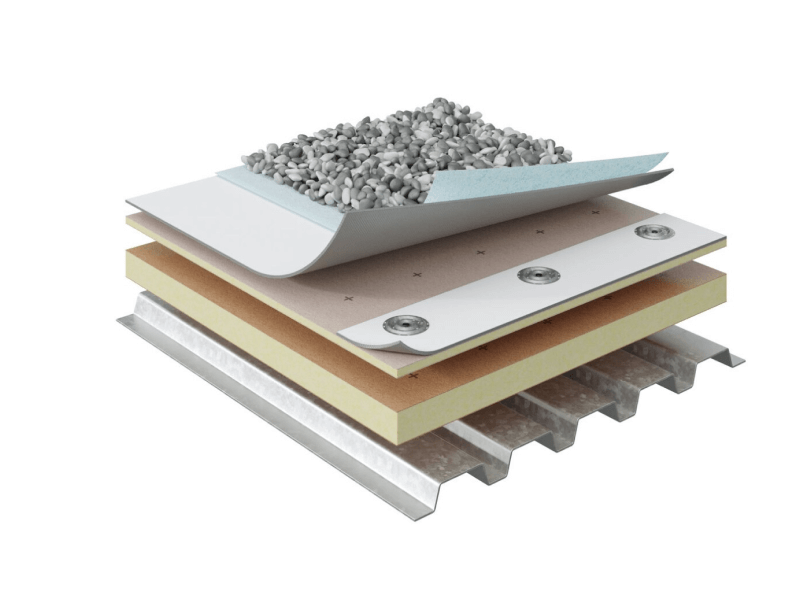

The system operates through these core steps:

- Substrate Preparation: The roof deck (metal, concrete, or wood) is cleaned and inspected for structural integrity.

- Membrane Laying: The PVC membrane is unrolled loosely over the substrate, allowing for thermal expansion without tension.

- Ballast Application: Uniform layers of ballast materials (e.g., 25-50 kg/m² of concrete pavers or gravel) are distributed across the membrane. The weight must be calculated to counteract wind uplift forces.

- Perimeter & Detail Securement: Membrane edges at parapets or penetrations are mechanically fastened or adhered to prevent wind-driven uplift, while the field remains ballasted.

Key Advantages

- Non-Penetrative Installation: Eliminates roof deck punctures, reducing the risk of water infiltration through fastener holes.

- Rapid Construction: No curing time for adhesives or complex fastening is needed, enabling installation in as little as 50% of the time required for adhered systems.

- Climate Resilience: Unaffected by temperature or humidity, allowing year-round installation in extreme weather (e.g., cold, rain, or heat).

- Design Flexibility for Green Roofs: Ballast materials (soil, aggregate) can double as the base for vegetation layers, supporting sustainable “green roof” designs.

- Cost-Efficiency for Occupied Spaces: Reduces downtime in occupied buildings, as noise and disruption from mechanical fastening are minimized.

Applications: Where Ballasted Systems Excel

- Ballasted systems are particularly suitable for:

- Walkable Roofs: Commercial rooftops used for recreation, solar installations, or equipment access, where the ballast provides a stable walking surface.

- Green Roofs: The ballast layer supports planting soil and vegetation without penetrating the waterproof membrane, ideal for urban sustainability projects.

- Large-Span Commercial Buildings: Warehouses, airports, or shopping malls with flat roofs, where rapid installation and wind resistance are critical.

- Roof Retrofits: Overlaying existing roofs without tear-off, as the ballast weight can be calculated to suit the structural capacity of older decks.

- Areas Requiring Easy Access: Membrane repairs or inspections are simplified, as ballast can be temporarily removed without damaging the system.

Technical Considerations for Ballasted Systems

Industry-leading ballasted solutions emphasize:

- Wind Load Engineering: Ballast weight is calculated using ASCE 7 standards, typically requiring 1.5-2 times the design wind uplift pressure.

- Ballast Material Selection: Gravel, concrete pavers, or precast blocks are chosen for durability, uniformity, and fire resistance (e.g., non-combustible aggregates).

- Drainage Design: Slight roof slopes (≥2%) and ballast spacing ensure water runoff, preventing ponding that could compromise membrane integrity.

- Sustainability Integration: Recycled concrete pavers or permeable ballast systems can enhance LEED credits for green building projects.

Ballasted roofing systems redefine efficiency in flat roofing by combining non-penetrative installation with rapid deployment. Their suitability for walkable and green roof applications makes them indispensable in modern urban architecture, where sustainability and functionality coexist. As cities prioritize green infrastructure and occupied rooftop spaces, the ballasted system’s ability to balance waterproofing, load-bearing capacity, and design flexibility positions it as a cornerstone of contemporary roofing technology.