What Is a Fully Adhered Roofing System?

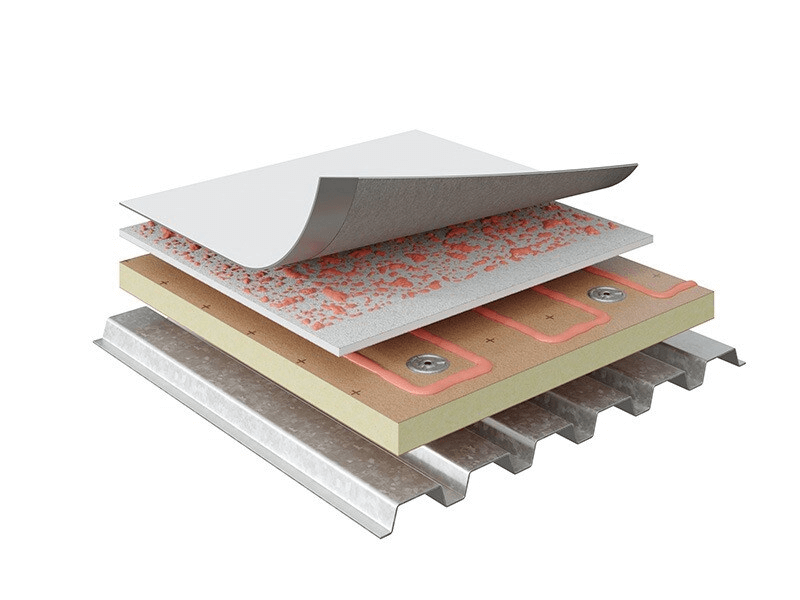

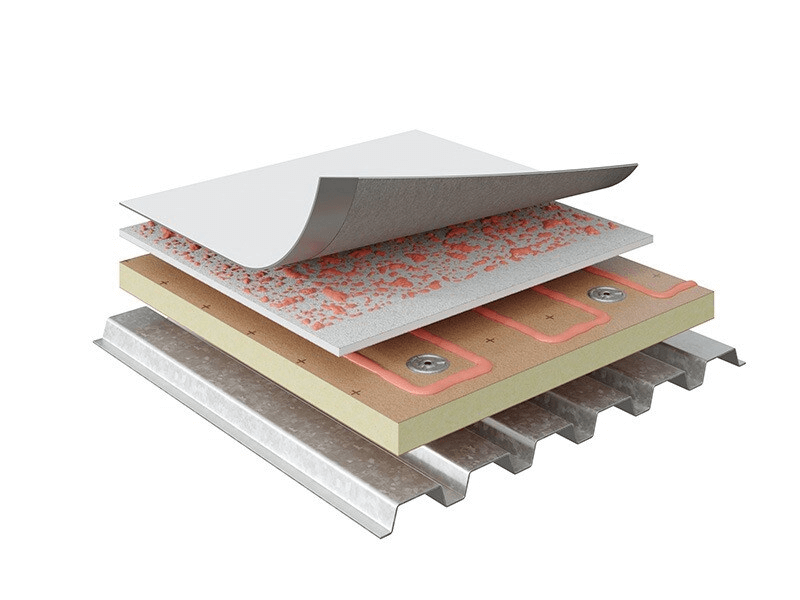

A fully adhered roofing system refers to a method of installing single-ply roofing membranes with non-woven fabric backing onto concrete or mortar substrates using approved adhesives. This technique creates a seamless, watertight bond, eliminating mechanical fasteners and relying on adhesive strength to resist wind uplift and environmental stresses. Unlike mechanical fastening systems, it offers a smooth, aesthetically pleasing surface ideal for complex architectural designs.

How Does It Work?

The installation process involves:

- Substrate Preparation: The concrete or mortar deck is cleaned, repaired for defects, and primed to ensure adhesive compatibility.

- Adhesive Application: Approved adhesives (often solvent-based, water-based, or hot-melt) are applied evenly across the substrate using rollers or trowels.

- Membrane Laying: The single-ply membrane (commonly PVC, TPO, or EPDM) with non-woven backing is unrolled and pressed into the adhesive, eliminating air bubbles.

- Seam Welding: Edges of adjacent membranes are heat-welded to form continuous joints, enhancing waterproofing.

Key Advantages

- Aesthetic Versatility: The smooth, fastener-free surface allows for architectural creativity, ideal for complex roof shapes, curves, or visible roofing areas.

- Design Flexibility: Perfect for roofs with intricate details (e.g., dormers, skylights, parapets), as the adhesive conforms to irregular contours without mechanical restrictions.

- Superior Waterproofing: The fully bonded membrane minimizes risk of water infiltration, as there are no penetrations from screws or anchors.

- Energy Efficiency: Reflective membranes (e.g., white TPO) can be used to reduce heat absorption, complementing the system’s airtight seal for improved thermal performance.

- Suitability for Renovations: Ideal for retrofitting over existing smooth-surface roofs, reducing tear-off costs and landfill waste.

Applications: Where Fully Adhered Systems Excel

Fully adhered systems are widely used in:

- Public Buildings: Schools, hospitals, and government offices requiring aesthetic appeal alongside durability.

- Commercial Structures: Office buildings, hotels, and sports centers with complex roof designs.

- Residential Projects: High-end apartments and condominiums where roof aesthetics matter.

- Renovation Projects: Overlaying existing roofs with smooth substrates (e.g., concrete or old adhered membranes) without extensive demolition.

- Low-Slope or Flat Roofs: Where water drainage relies on the membrane’s waterproofing rather than steep slopes.

Technical Considerations for Fully Adhered Systems

Industry-leading fully adhered solutions emphasize:

- Adhesive Technology: Advanced formulations (e.g., moisture-cured polyurethanes) ensure bond strength in varying climates.

- Wind Uplift Resistance: Calculated adhesive coverage (typically 100% for high-wind zones) meets or exceeds codes like ASCE 7.

- Sustainability: Recyclable membrane materials and low-VOC adhesives align with green building standards (e.g., LEED).

- Certification and Testing: Systems undergo rigorous evaluation (e.g., FM Global 1-90, UL 1598) to validate performance.

Fully adhered roofing systems combine aesthetic excellence with technical reliability, making them a preferred choice for projects demanding both design flexibility and robust waterproofing. From complex public buildings to renovation initiatives, their ability to conform to intricate geometries while delivering long-term durability underscores their role in modern construction. As adhesive and membrane technologies advance, these systems continue to set standards for seamless integration of form and function.