What Is a Mechanical Attached Roofing System?

A mechanical fastening(attached) roofing system refers to a method of installing single-ply roofing membranes, typically PVC (polyvinyl chloride), by securing them to the substrate using approved screws and washers. This technique is designed to resist wind loads and ensure long-term waterproofing, making it a staple in modern commercial and industrial construction. Unlike adhesive or fully adhered systems, mechanical fastening relies on physical anchors, creating a robust connection that withstands harsh environmental stresses.

How Does It Work?

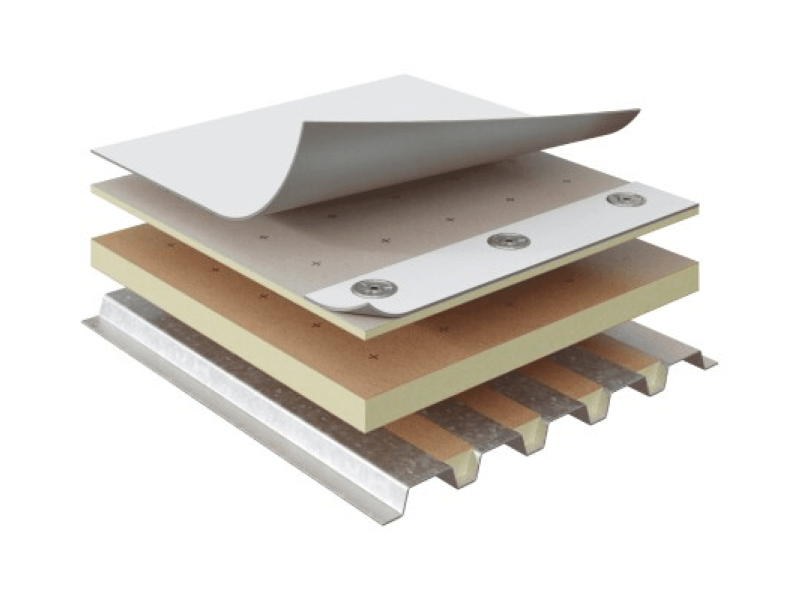

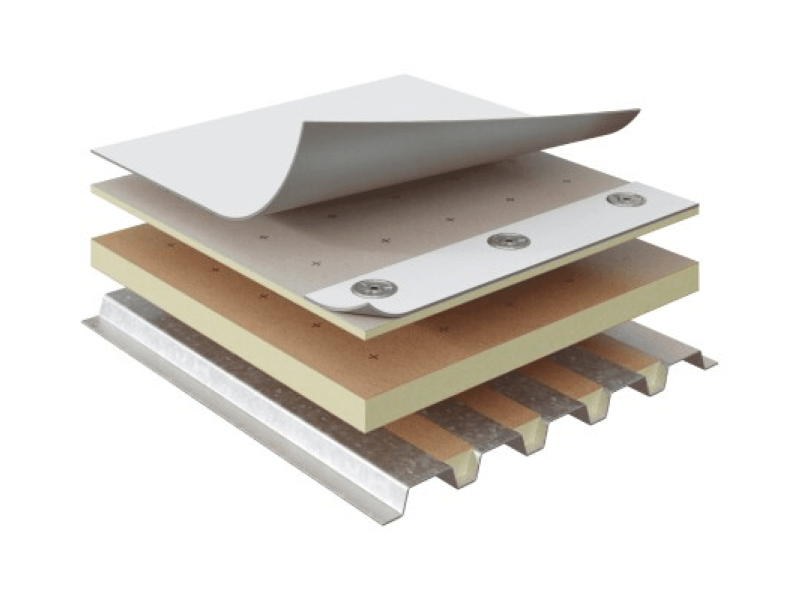

The system operates on a straightforward principle:

- Substrate Preparation: The roof deck (often metal, concrete, or wood) is cleaned and inspected for uniformity.

- Membrane Laying: The PVC membrane is unrolled over the substrate.

- Anchoring: Specialized screws with large-diameter washers are driven through the membrane and into the deck, distributing wind forces across a wider area. The spacing of anchors varies based on wind load calculations and local building codes.

- Seaming: Membrane panels are heat-welded at the edges to form a continuous, watertight surface.

Key Advantages

- Rapid Installation: Mechanical fastening allows for quick deployment, as it eliminates the need for adhesives to cure or weather-dependent bonding. This speed is critical for large projects with tight deadlines.

- Climate Resilience: The system is nearly unaffected by temperature or humidity, enabling installation in cold, wet, or hot conditions—an advantage over adhesive systems that require specific weather windows.

- Wind Resistance: By directly anchoring the membrane to the structure, mechanical systems excel in high-wind regions, often exceeding code requirements for hurricane-prone areas.

- Cost-Efficiency: Reduced labor time and minimal weather-related delays lower overall project costs. Additionally, the durability of PVC membranes (20+ years lifespan) minimizes long-term maintenance.

- Design Flexibility: Suitable for both flat and low-slope roofs, the system accommodates complex roof geometries, such as parapets, penetrations, and curbs, with ease.

Applications: Where Mechanical Fastening Shines

Mechanical fastening systems are ideal for large-scale light-gauge steel structures, including:

- Industrial Warehouses: Vast roof areas require durable, quickly installed solutions.

- Logistics and Distribution Centers: High ceilings and expansive footprints demand systems that balance speed and wind resistance.

- Supermarkets and Retail Chains: Large, flat roofs benefit from the system’s energy efficiency (PVC membranes are often white, reducing heat absorption).

- Manufacturing Plants: Resistance to chemicals and mechanical damage makes PVC a top choice for industrial environments.

Technical Case Study: Typical Mechanical Fastening Systems

Leading mechanical fastening solutions in the industry exemplify the technology’s potential through:

- Engineering for Light Steel Structures: Systems designed specifically for factories and logistics hubs integrate seamlessly with steel decking.

- Advanced Wind Load Solutions: Finite element analysis optimizes anchor placement to withstand up to 180 mph wind speeds.

- Sustainability: PVC membranes are recyclable, and the system’s long lifespan reduces material waste.

- System Certification: Compliance with global standards (e.g., FM Global, UL) ensures reliability for architects and owners.

Mechanical fastening roofing systems, particularly those utilizing PVC membranes, have revolutionized commercial roofing by prioritizing speed, resilience, and cost-effectiveness. From large-scale industrial projects to modern commercial buildings, their ability to thrive in diverse climates and resist extreme weather makes them an indispensable tool in contemporary construction. The future of roofing lies in merging mechanical reliability with sustainable design, as seen in the ongoing innovation of industry-leading systems.